Smart age, grasp the future - predictive maintenance of valves

Release date:2024-07-11Click:146

Process manufacturers have long pursued the goal of predictive maintenance by deploying devices to monitor potentially malfunctioning equipment while allowing healthy equipment to continue operating. The realization of this goal can greatly reduce the maintenance cost of production enterprises and effectively avoid unexpected power outages and shutdowns. In theory, every business should take this predictive approach to maintenance, but few companies can achieve this goal because predicting the future has many difficulties in practice.

This article will introduce some diagnostic and data processing measures for predictive maintenance. These measures have been put into practice and have achieved certain results in the automation valve industry, and are in continuous development and update.

01、Active maintenance vs. passive maintenance

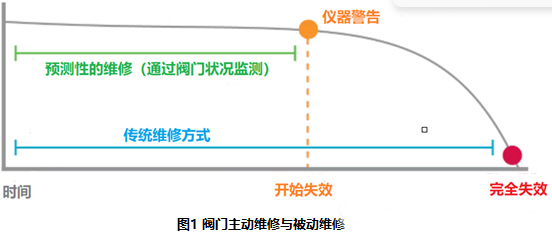

Automatic control of on-off valves is a critical component in the process industry, and their accidental failure can cause millions of dollars in losses each year. When the automatic control valve is set to automatic mode (as is usually the case), the controller compensates when valve performance deteriorates, allowing the loop to continue operating in the event of valve performance degradation until the valve eventually fails completely, disrupting the process or forcing shutdown. During the whole process, the automatic control valve did not provide obvious warning information.

In fact, there will be signs of any impending failure, although these signs may be very insignificant (Figure 1). If these signals can be detected and acted upon, the parts that need to be repaired can be located in time, and a short power outage or bypass can be arranged to make repairs, minimizing production losses caused by unexpected accidents.

The key to predictive maintenance is data, and the more data you have, the more accurate your predictions will be. Traditional automated valves only collect valve position data and cannot provide the rest of the necessary data. With the development of intelligent diagnostic digital valve controllers, more and more data can be obtained. These digital valve controllers use a series of sensors to monitor valve operation and detect anomalies. Some high-end controllers allow offline and online monitoring, which can capture initial valve installation data and compare it with operational data, recording differences. This on-line monitoring can capture the performance data of the valve in operation and some transient problems, which is difficult to achieve in the traditional case.

02、It's the data you use that counts

Data is the key to predictive maintenance. Only professional think tanks receive these data and conduct professional evaluation of them in order to obtain more accurate prediction results. The whole process has been hampered by the following issues.

(1) The installed valve controller may be an older model that lacks the ability to monitor and capture the necessary data.

(2) The digital valve controller can capture data, but it cannot transmit this data, and technicians must come to the site to obtain the data.

(3) The digital valve controller is connected to the maintenance network and transmits data to a public location, but the relevant personnel lack the relevant knowledge and experience to understand this data information and draw feasible conclusions.

Hardware input

The first problem will resolve itself over time. As the old valve controller fails, most users will replace it with a new intelligent digital valve controller. Using advanced sensor and communication technologies, these valve controllers are available in different performance levels, with high-end products providing downtime detection, operational diagnostics, and partial stroke testing.

If companies want to achieve predictive maintenance, they need to invest more in digital valve controllers, including in-service valves and new valves, especially those that operate under harsh conditions and are critical to production. Improved diagnostic capabilities, reduced maintenance costs and increased uptime make the investment in digital valve controllers pay for itself in a short period of time.

Data transmission

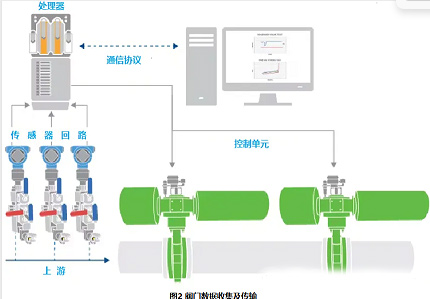

The second problem is that of data transmission, which has also been effectively solved with the development of information and communication technologies. The new intelligent digital valve controller can transmit data via wired or wireless communication protocols (Figure 2). Predictive maintenance is only possible if data is continuously accessed and monitored in real time. The enterprise extracts data through the control system and transfers it to a public location where it can be consulted, or to other predetermined locations.

Remote think tank

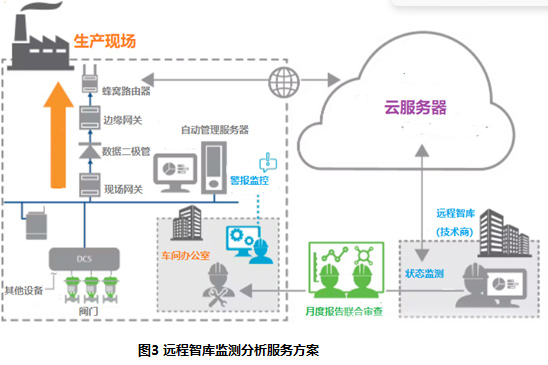

The most difficult place to achieve predictive maintenance is to find a specialist think tank. A specialist think tank can conduct a professional assessment of the captured data, diagnose ongoing problems and take appropriate action to address them in advance and avoid complete valve failure. Some large companies already have solutions, and more are being developed.

The Fisher FIELDVUE ValveLink software system, for example, automatically performs scheduled in-line inspections while valves are in operation, continuously monitoring and alerting air pressure, performance degradation and packing problems. Future software may use applications with built-in machine learning and artificial intelligence to flag emerging problems and propose solutions.

If a factory lacks a specialized think tank to monitor valve information, it can securely transmit the data to remote experts with extensive experience who can act as an extension of the field staff. Experts can communicate to plant personnel about emerging long-term problems and those that require an immediate response (Figure 3). This remote service can monitor valve performance degradation and predict upcoming failures before the valve completely fails, which can effectively reduce the pressure on production enterprises. This also provides an opportunity for plant personnel to interact with valve experts on an ongoing basis to consult on valve performance and improvement measures.

03, data investment return case

One herbicide plant used advanced control valve diagnostics to switch from reactive to predictive maintenance, reducing maintenance costs by $230,000 per year. In one case, the plant saved nearly $100,000 by monitoring a faulty control valve and taking preventive repairs before the valve completely failed.

A refinery found that 26 critical valves in its hydrocracking unit could lead to an unplanned shutdown. But refiners lack think tanks specializing in valves, so they hire valve suppliers to provide remote services to continuously monitor these valves and report problems. The think tank detected a leak in a large anti-surge valve and problems with multiple heating valves. Using this information, repairs were made without downtime, avoiding $5.6 million in unplanned downtime and saving $400,000 annually by improving the performance of heating units.

04, grasp the future

Predicting the future is not easy, but when the necessary data can be collected and transmitted to professional think tanks, it becomes possible to predict the future. With the development of digital valve controllers, a new generation of digital valve controllers will be able to collect and provide more data. This data is captured and transmitted to the correct location, and through advanced software and remote think tank/expert processing, this data information can be converted into concrete actions that can be taken to enable predictive maintenance and avoid complete failure.

New communication technologies such as Ethernet APL and local real-time control have enabled the rapid development of digital valve controllers and improved predictive accuracy, thereby reducing maintenance costs and improving uptime.

The intelligent upgrading of equipment, combined with remote expert services when necessary, will bring huge returns to enterprises in the future. And as its performance improves over time, predictive maintenance will eventually become possible.