PRODUCTS MACHINING

It is not enough to have good management, good idea and good talents, but also have excellent equipments to represent that the enterprise has strong production capacity and ensure the excellent quality of the products. WoD has introduced production and processing equipment and technical talents, with high-precision CNC machine tools, large-scale processing equipment and special process equipment, which provides a strong guarantee for product quality and enterprise development

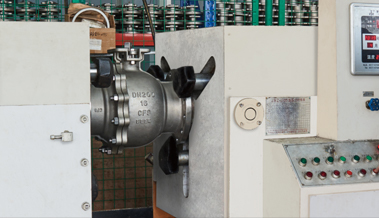

TESTING EQUIPMENT

In order to improve the product detection and testing, WoD has set up full-time quality inspectors for each link from the incoming material, machining process to the final shipment of the products to ensure 100% qualified products.We have a full set of advanced inspection and testing equipment to control the quality of our valves from rough castings and forgings to finished products. These equipments enable us to carry out the following inspections: material composition spectral analysis, material tensile test, material impact test, material metallographic analysis, hardness test, ultrasonic non-destructive testing, pressure performance test, penetration testing, magnetic particle testing, roughness meter and others.